| Home | Latest News | Passed Sessions BIMS-1 | Passed Sessions BIMS-2 | Our Customers | Seminar Content | Documents | Send Message |

IMPORTANT NOTE : BIMS-1 and BIMS-2 ARE TRAININGS ON TWO DIFFERENT TOPICS AND THERE IS NO PREFERRED SEQUENCE. YOU CAN ATTEND ONE OR BOTH IN WHATEVER ORDER YOU PREFER

BIMS-1 UNDERSTANDING INJECTION MOLDING OF THERMOPLASTICS

Seminar's Scope

This seminar will focus on complex phenomena behind the Injection Molding process, with strong emphasis on the understanding of part's problems (aspect, shrinkage, warpage, weld lines, burns, ...) and their relationship to material properties (amorphous, semi-cystalline, filled, unfilled) and the process itself.

The participants we expect could be :

- design engineers in charge of molded parts

- mold making specialists

- molders

- flow analysts looking for analysis interpretation support

- project leaders involved in developing molded parts

- research engineers interested in injection molding

- mechanical engineers interested in process induced weakness and strength

- material engineers or designers whishing to improve their understanding of a given class of materials (i.e. glass fiber filled polymers).

- students involved in the field

- young, skilled professionals with little field experience

- flow analysis developers

- customer support engineers

The BIMS-1 seminar content

- Basic polymer thermal and rheological behaviour.

- Effect of pressure on polymer properties.

- The flow process in Injection Molding.

- Part geometry and flow pattern.

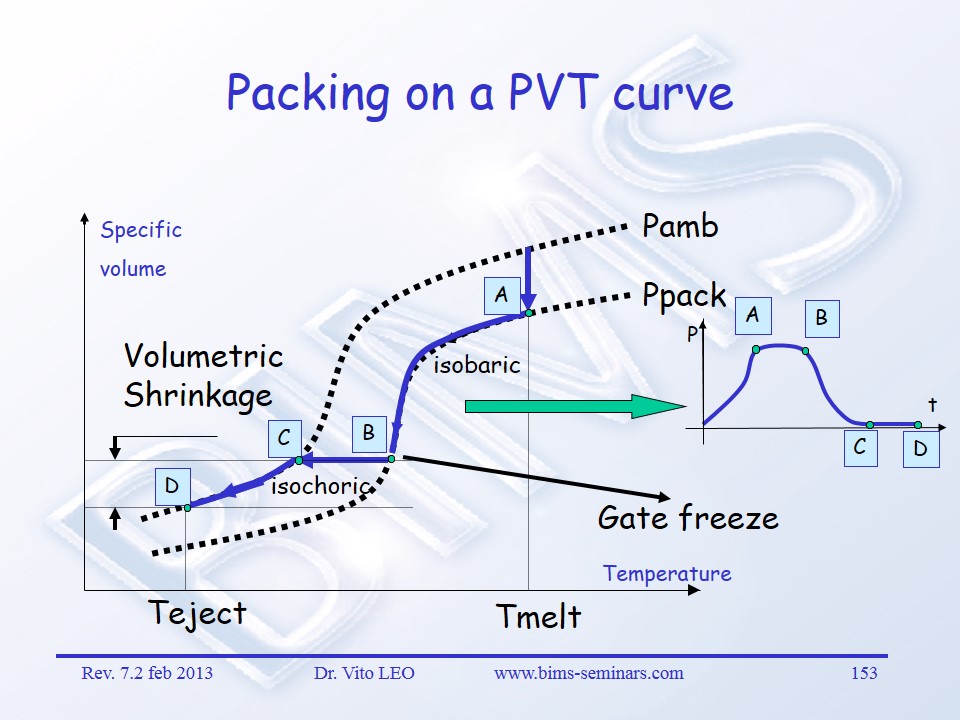

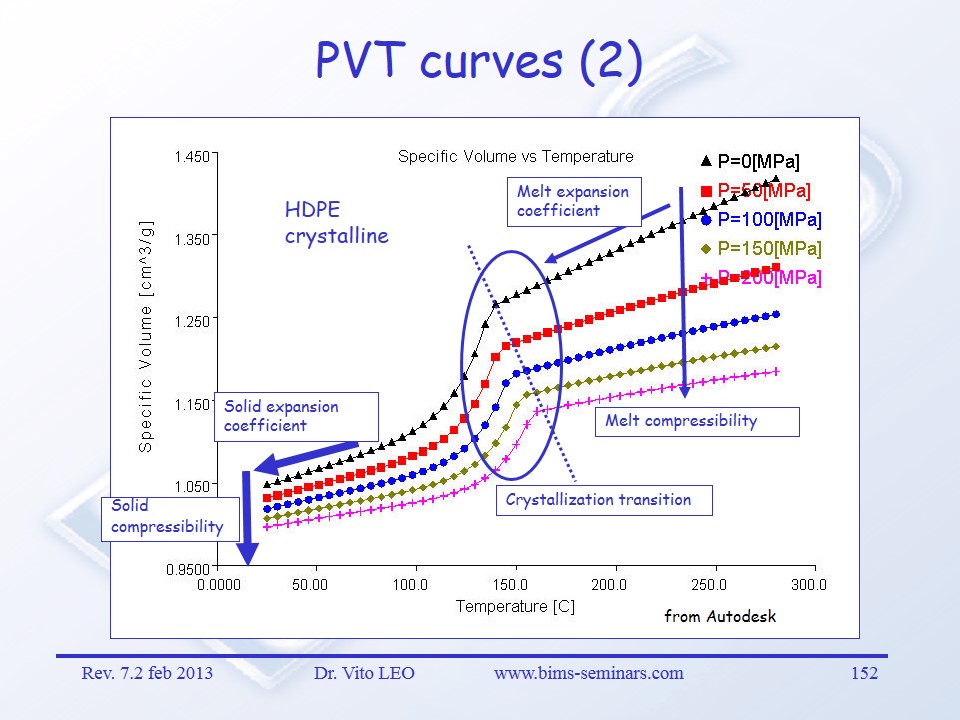

- Compressibility, phase change and PVT data.

- What is crystallinity and how does it affect processing?

- The packing phase: key to the dimensional quality of the part.

- Effective part, mould and process design for proper cavity packing.

- Understanding the shrinkage build-up.

- Part warpage mechanisms: designing for minimum warpage, according to material properties and part shape.

- Warpage: the special case of fibre filled materials.

- The concept of residual stresses: the compromise with warpage.

- Final conclusions and wrap-up - Seminar evaluation by the participants.

The seminar is not specifically about Injection Molding Simulation. However, the intention is to clearly help those among the participants who are "Flow Analysis users" to gain a thorough understanding of the concepts that form the basis of existing code. Model assumptions and corresponding limitations will be highlighted and discussed.

The

seminar will be highly interactive, with limited attendance, allowing

for questions, group discussion and analysis of the attendant problems.

Parts or drawings are welcome for open discussion, when possible.

The first part of the seminar will quickly describe the

process cycle for the purpose of setting up a common vocabulary.

The seminar may not fit the needs of beginners in the field.

BIMS-2 UNDERSTANDING MECHANICAL PROPERTIES OF THERMOPLASTICS

Over the years, Vito LEO, has also developed a large experience in the field of Mechanical Properties of Polymers and after a long preparation has decided to offer a new seminar to the Plastics Community.

It appeared indeed that, similar to the subject of Polymer Processing, many professionals involved in plastic part design or materials specialists, have a relatively poor understanding of the very complex thermo-mechanical performance of polymeric materials or compounds. This is however often a critical knowledge considering the frequently complex failure phenomena observed in plastics (creep, impact, environmental stress cracking, plastic yielding, crazing, brittle failure,…).

The subject is both very wide and extremely challenging. The ambition of this new BIMS seminar (BIMS II) is to provide an in depth introduction to the participants, regardless of their scientific background or specific experience in the field.

Two days is too short to get very deep into the details, but more than adequate to explore quite deeply the subject, establishing a solid knowledge base for all participants, and preparing them to consider more specialized reading or training in their particular field of interest within the area

Seminar's Scope

- design or mechanical engineers working with plastics

- molders interested in part performance

- professionals interested in plastic part failure mechanisms

- FEA specialists

- project leaders involved in developing plastic parts

- research engineers interested in polymer performance

- material specialists or designers wishing to improve their understanding of mechanical performance of a given class of materials (amorphous, crystalline, filled or unfilled).

- students involved in the field of polymers

- young, skilled professionals with limited experience in the field

- seasoned professionals looking for a fresh view on (or review of) polymer mechanical performance

- flow analysis specialists wishing to extend their knowledge to the field of mechanical performance

- customer support engineers

- scientists

- ….

The teaching material (over 200 slides) provides an in depth introduction in the field of plastic mechanical performance.

After attending the seminar, we expect the participants to have a fairly good answer to many typical questions that often come-up when dealing with plastics, like, for instance:

- Why does the modulus of plastics change so much with temperature? Why is this change so different from one polymer to another ?

- Why do amorphous polymers generally fail in a brittle way in long term tests or impact ? Why do some still perform quite well in these conditions ?

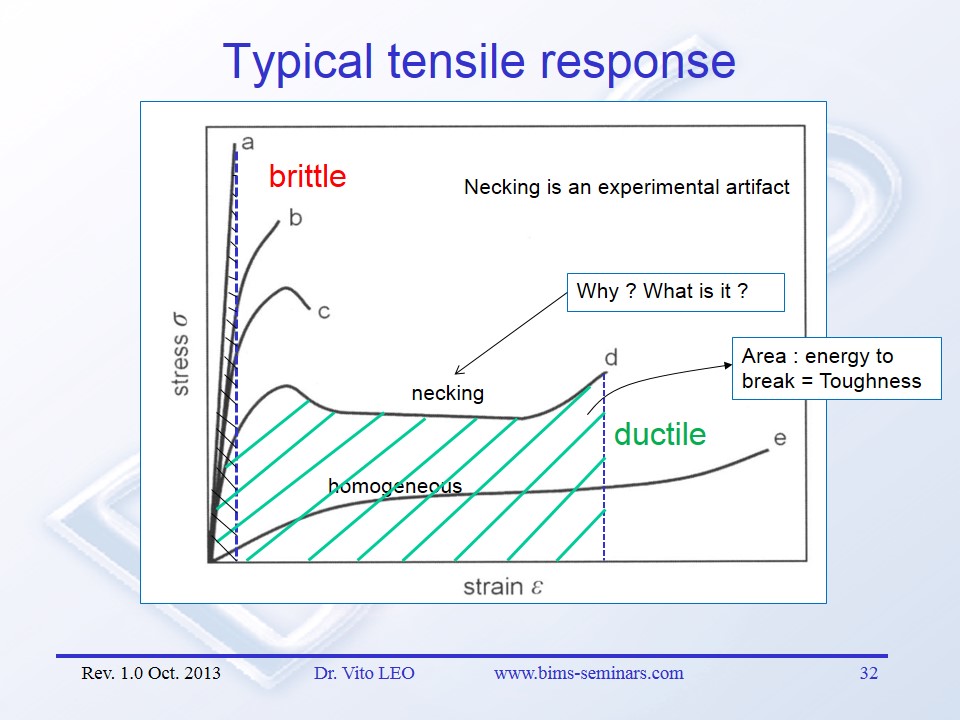

- Why do we have such a thing as a “brittle-ductile” transition in polymers ? What is it exactly ? Why are some polymers ductile at some test rates and brittle at lower as well as higher strain-rates ? Why is the test “timing” so important for plastics ?

- Why does plastic performance change so much with processing conditions, even when unfilled, and even when amorphous ?

- Why do polymers “age” ? What does this mean and what are the implications on performance ?

- What are the mechanisms behind rubber reinforcement ? Why is the morphology of these blends so critical ? Why do we need to tailor the formulations to every specific polymer ?

- What is Yielding ? What is plastic flow ? Why do some polymers “shear-band” and neck in a tensile experiment, and some don’t ?

- What is the role of crystallinity in mechanical properties of plastics ?

- Why does a polymer, at the same temperature, generally fail at very different times and stress levels in short vs. long term (creep) tests ? Is there a way to predict long term performance from shorter terms tests ?

- How can we measure properly the intrinsic mechanical properties of polymers at large strains without artifacts (necking) or premature failure ?

- Why do glass fiber increase modulus and strength but reduce elongation at break ? What are the reinforcing mechanisms ? How critical is the interfacial strength between matrix and filler ? What is the optimum fiber length ?

- Why do we test plastics with and without a “notch” ? What is really happening at the notch ? Why do some polymers still perform when notched and some don’t ?

- …………..

The list of questions would be very long, but the ones listed above give at least a good idea of the general approach of the seminar. No “recipes”, but mainly focus on “understanding” so that any new question, new problem, new polymer can hopefully be addressed and examined with the right concepts in mind.

Many of the subjects presented are supposedly well-known and largely described in text-books or scientific literature. However, the reality is often that the subject appears to be daunting making it very difficult or almost impossible to find the necessary knowledge, presented in a comprehensive but understandable way, within a concise text.

The seminar may not fit the needs of beginners in the field, although our intention is to present material requiring no pre-requisite knowledge. Conversely, specialists in the field may find this 2 day’s training too general to fit their needs. We believe however that this seminar may bring a fresh view on classical material which will provide useful understanding and interpretation tools to all participants.

Compared to the now classical BIMS seminar on Injection Molding, this training on mechanical properties is somewhat more challenging in terms of theoretical content. We count on the attendants’ active participation to bring up examples of plastic part failures or other mechanical related issues, in order to make the session as interactive as possible. As observed over the years with our BIMS I seminar on Injection Molding, we will enrich the presentation with more and more practical examples provided by the participants as we go. We thank you in advance for your help and material (parts, drawings, pictures, examples, good stories…).

The session “zero” of this seminar has been already presented privately to specialists in the field at Novo Nordisk (Oct. 2013), and was largely appreciated.

We now have presented BIMS-1 about 15 times.

We hope to see you soon at a coming session of this training ! Check the latest news page for the agenda of coming dates or contact us for a private session in your company or institute.

.